Technology and

artisan precision

A completely internal, traceable and flexible process.

Each insole speaks about us.

1

Total control, guaranteed quality

IN-HOUSE PRODUCTION FOR PRECISION, SPEED AND FLEXIBILITY

We manage the entire production cycle in our headquarters in Porto Sant'Elpidio: from CAD design to laser cutting, up to manual finishing and quality control. We produce up to 6000 pairs per day, offering rapid turnaround times, high reliability and maximum customization. Each phase is followed by specialized workers with over 20 years of experience, to guarantee high standards in every detail.

2

Innovation and tailor-made care

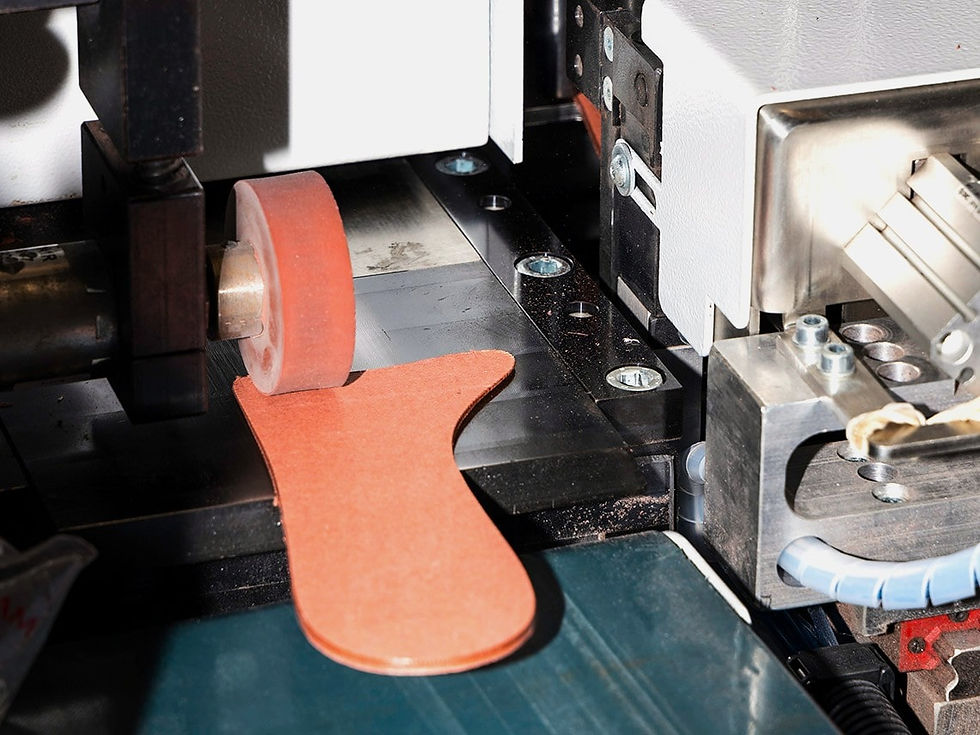

ADVANCED TECHNOLOGY AND PROPRIETARY MODELING

We invest in cutting-edge technologies such as 3D scanners, CNC cutting and automatic milling to ensure precision and quality. Our in-house model makers develop samples on request, ensuring confidentiality and maximum customization. A perfect balance between automation and artisanal attention at every stage of the process.

3

Excellent materials, guaranteed comfort

CUSTOM INSOLES WITH CERTIFIED MATERIALS

We only use certified and high-performance materials such as texon, poron, leather and memory. Each insole is hand-finished, with custom workmanship designed to facilitate assembly and improve the final comfort of the shoe. Quality is felt, step after step.

.jpg)

Spiders in salpa/texon

.jpg)

Skivings, heels and recesses

.jpg)

Milling, pressing, injections